Electrical

& ELECTRONIC

We offer specific copolymers for several applications and processing in the Electrical and Electronic markets.

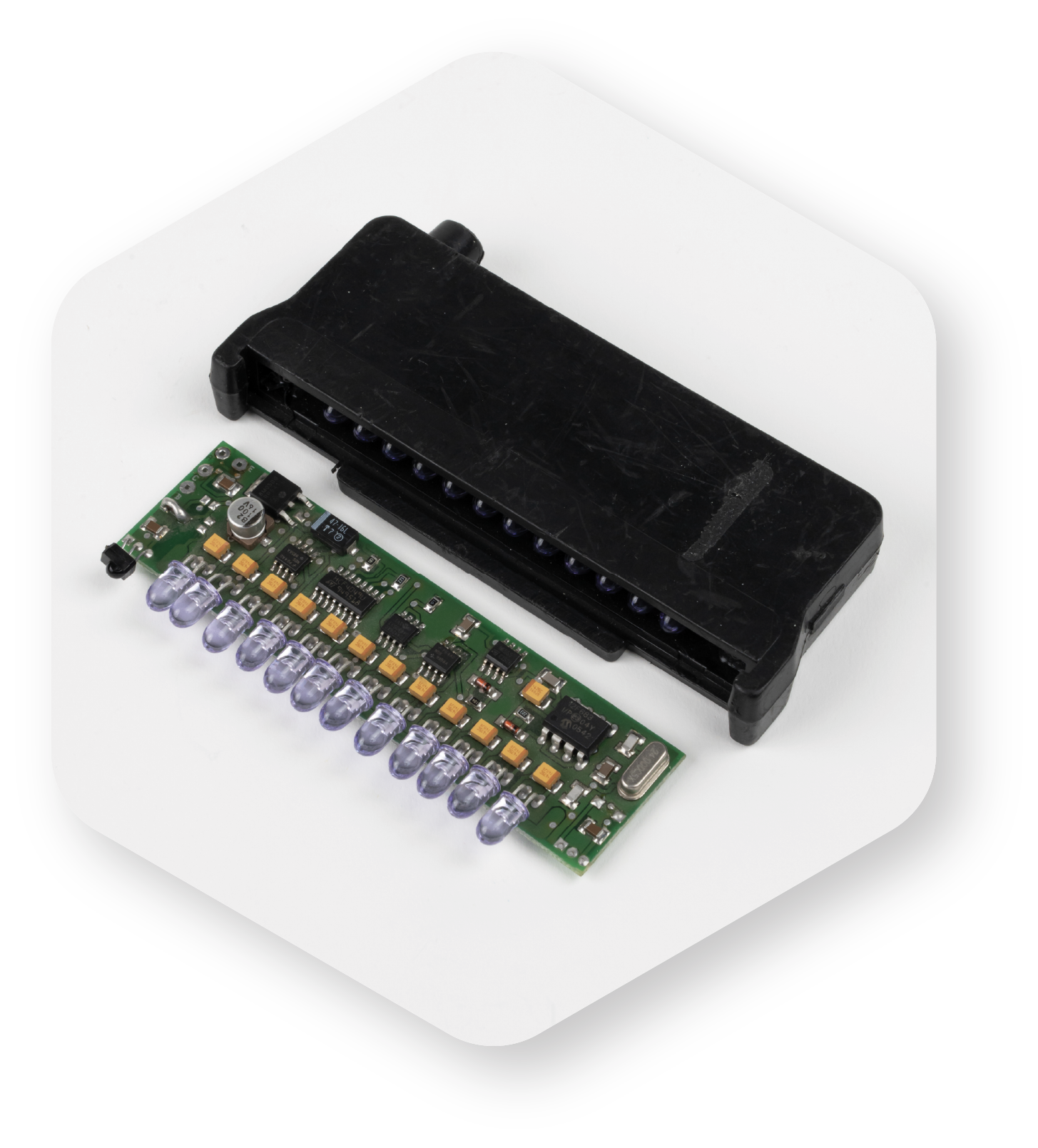

Their easy processability at low pressure is suitable for overmolding and potting processes. Our wide range of hot melt grants easy 1K solution for an excellent protection of print circuit board (PCB) and electronic components from critical environment conditions as shock, dust, humidity, chemicals, UV exposure and temperature.

For the Electrical segment, we offer co-polyamide grades suitable for Heat Shrinkable Tubing.

Our TPC solutions find wide application in wire & cable jacketing segment, combining electrical insulation with superior flexibility and the easy processability of thermoplastics.

The high performances of our polymers allow a compact design with thin walls and weight reduction, contributing to a cost saving.

We offer specific copolymers for several applications and processing in the Electrical and Electronic markets.

Their easy processability at low pressure is suitable for overmolding and potting processes. Our wide range of hot melt grants easy 1K solution for an excellent protection of print circu-it board (PCB) and electronic components from critical environment conditions as shock, dust, humidity, chemicals, UV exposure and temperature.

For the Electrical segment, we offer co-polyamide grades suitable for Heat Shrinkable Tubing.

Our TPC solutions find wide application in wire & cable jacketing segment, combining electrical insulation with superior flexibility and the easy processability of thermoplastics.

The high performances of our polymers allow a compact design with thin walls and weight reduction, contributing to a cost saving.

Copolyamide based hotmelts, with a renewable source content, applicable in a solvent-free environment.

e‐TECHNIPOL®PA are characterized by high flexural modulus, superior resistance at low temperature and excellent adhesion to metals and polar plastic substrates; in addition, several grades e‐TECHNIPOL®PA are classified UL94-V0. Thanks to their intrinsic properties, e‐TECHNIPOL®PA can be processed with melters, low pressure molding, potting and overmolding.

Copolyester based hotmelts applicable in a solvent-free environment.

e‐TECHNIPOL® are characterized by high flexural modulus, superior resistance at low temperature and excellent adhesion to metals and polar plastic substrates; in addition, e‐TECHNIPOL® products boast an excellent chemical resistance to alcohol and solvents and food contact compliances. Thanks to their intrinsic properties, e‐TECHNIPOL® can be processed with melters, low pressure molding, potting and overmolding.

Co‐polyamide hot‐melt adhesive, specifically designed for Heat Shrinkable Tubing and Heat Shrinkable Sleeve production.

e‐TECHNIPOL®PA 7115 is characterized by high viscosity, low softening point and very good flexibility, with an excellent adhesion on non-polar substrates as PE. It shows very high resistance to physical curing processes of PE and to expansion/shrinking operations.

Thermoplastic ether-ester elastomer (TPC-ET), available in a broad range of hardnesses and melting temperatures.

SIPOLPRENE® matches flexibility over a wide temperature range, chemical resistance and the easy processability of a thermoplastic.

These copolymers, with their high dielectric constants and good dissipation factors, are suitable for wire and cable jacketing, where electrical insulation combined with protection from external environment and mechanical abrasion are needed.

DISCOVER OUR

APPLICATIONS

CABLE JACKETING

SIPOLPRENE®

ELECTRONIC CIRCUIT ENCAPSULATION

e-TECHNIPOL®

e-TECHNIPOL®PA

HEAT SHRINKABLE TUBING

e-TECHNIPOL®PA 7115

CERTIFICATIONS